Under the WP6, Industrial Scale-up, TU Wien is supporting WP 6 with simulation tasks for the overall process in Aspen Plus. Up to now, the focus was put mainly on potential in-situ recovery methods. The results generated in other work packages were used to develop simulation models for adsorption, stripping, pervaporation, distillation as well as coupled approaches.

The latest development was a solution-diffusion based multi-component model for pervaporation process developed for Aspen Plus and parameterized with characteristic membrane values gained through work package 3. Combination with distillation offers first estimates for potential energy savings of up to 50% compared to the traditional production route. Furthermore, the effects of different membrane material on the butanol separation step were calculated.

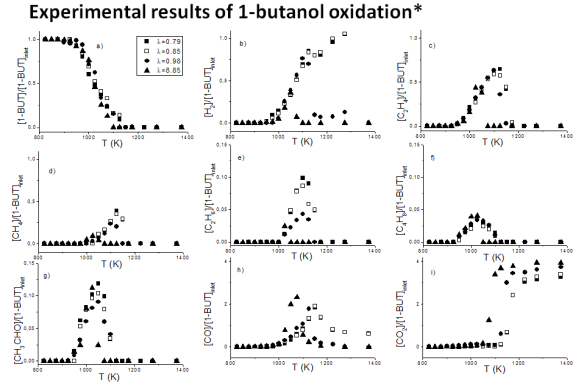

UNIZAR has carried out combustion tests. Oxidation experiments of 1-butanol have been performed for different oxygen concentrations that go from fuel-rich to fuel-lean conditions.

The results showed:

Increasing the amount of oxygen in the reactor inlet causes a shift in the conversion onset of 1-butanol to lower temperatures.

The stoichiometry also affects the temperature of formation of products and the temperature where they reach their maximum concentration.

Increasing stoichiometry influences the hydrocarbons concentrations obtained (CH4, C2H6 and C4H8) that are produced in low amounts.

The kinetic model of different hydrocarbons and alcohols reactions developed by UNIZAR has been updated with a subset for describing the oxidation of 1-butanol. There is good agreement between the experimental and simulated results.